Walkway and Driveway Radiant Heating Systems

It has been a problem for decades to shovel snow off your driveway during winter season. Having car is not a luxury anymore and maintaining safe driveway has always been on our inconvenience list.

All of us have experienced with a snow surprise and early morning snow shoveling before going to work. The cheapest and easiest way was always to pay $20 to neighbor kid for cleaning all the snow from driveway but now there are more comfortable ways.

Today we are going to talk about radiant heating systems for driveway and walkway and here are the topics to cover:

- Types of Heater Systems Under Driveway

- What Other Benefits Does It Have

- Installation of Driveway Heaters

- Heated Driveway Costs Explained

- Maintenance Throughout the Year

- Lifespan of Heating System

- Hiring Contractor of Walkway Heating System

- Where to Purchase Driveway Heating Mats

This invention is definitely making life more luxurious for those of us who already have a house with a driveway and a car.

[instagram-feed]Types of Heater Systems under Driveway

Generally speaking there are two types of heaters systems that can be used for driveways and walkways of your home. They are both installed under the surface and radiate heat through few layers installed on top.

Water Heated Driveway or Hydronic System – plastic water pipes are installed under your driveway or walkway in loops. Each section (run) should cover maximum 400 sq ft, otherwise heat will not spread properly.

Water is filled inside these pipes and it constantly circulates from one end to another. Pipes are connected to manifold with several sections or single switch for shut off.

Water is getting heat up by water heater or boiler system that is installed inside the house.

Electrical Heated Driveway – prewired mats are connected together and installed under the pavement similar to water pipes.

Low electrical charge is sent through the wires and they warm up. This process increases temperature of surrounding materials (concrete and asphalt).

Electrical heated driveway system is connected to one power line that meets at thermostat or other controller and continues into electrical panel on dedicated breaker.

Both systems are relatively similar in process and function. Only difference is one has hot water running through that is heated up from boiler and electrical system gets heated up by electrical current and uses direct energy.

What Other Benefits Does It Have

Aside from being luxurious addition to your house, driveway radiant heating system has few other benefits that we would like to point out to our readers.

Safety – accumulation of snow and ice on driveway becomes dangerous issue for your family and anyone who walks on it. Especially businesses may sometimes have unfortunate slip and fall law suits. Heated systems prevent from such incidents and have you stop worrying about falling on ice.

Smart System – as new technology progressing, the whole world can be controlled from your phone. Driveway radiant heaters can also be connected to smart system that works on phone application. Imagine driving from airport and turning on driveway melting system and having all snow gone by the time you arrive.

Saving Money – by spending money on installation of electric or water heated driveway you can be saving in long run. When doing new driveway adding heaters is not that expensive and you will be not spending any money through the winter for salting bags and hiring someone to shovel the snow.

Selling Point – when you have driveway heaters installed, it is easier to sell the property or even increase the selling price. This feature will stand out from other properties on market and puts you ahead of competition. High end homes require as many unique features as possible and this is one of them.

Installation of Driveway Radiant Heating Explained

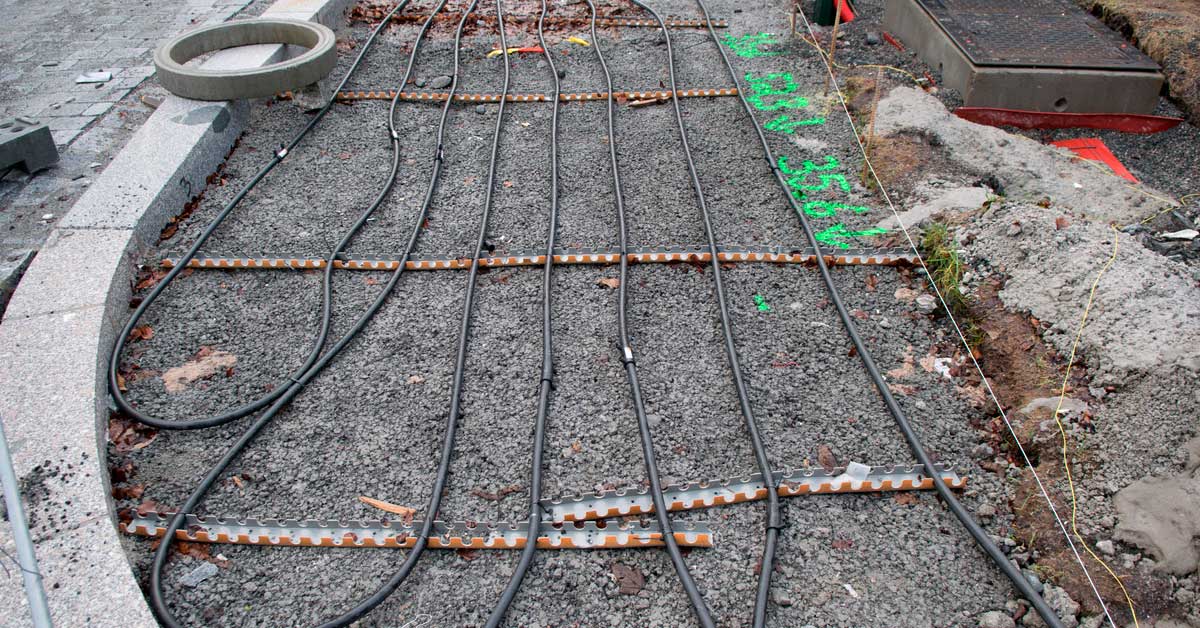

Pipes installed before concrete for heating.

Home owners that are interested in process of installation can see below On Point Remodeling Step by Step guide. Either trying to complete DIY project or monitoring contractor that you hired for driveway radiant heating installation, you can learn how it should be done here.

Demolition and Removal of Existing Driveway Surface – You can’t just install heating system on top of existing driveway. First step is removing the layers all the way to the ground/soil. This is done with specific machinery or excavator.

Preparation of Soil and Gravel with Leveling – To make sure your driveway does not sink in few years, we recommend stabilizing the ground by method of compaction. Gravel is leveled on top of stable soil to make subsurface even.

Running Tubes or Wire Mats – Next step is relatively similar for electrical and plumbing tubes installation. Specialists install heat transmission material along the perimeter you want to heat up. Matts come in sections that are connected one to another and plumbing tubes run in loop sections no more than 400 sq ft each.

Connection to Main Heat Source – The whole system is connected to main heat source that is usually placed inside the house. For water pipes it is either boiler or hot water tank, while wires are connected to electrical panel or breaker system.

Testing how Heating System Works – Before you close up thousands worth of work and material and install heavy construction on top we strongly recommend testing entire heating system several times.

Installation of Top Surface – Now it’s time to select what material to use for driveway and install it on top of heating mats or radiant heating system with pipes. Most preferred surface materials are poured concrete or asphalt.

Heated Driveway Costs Explained

Before any luxury feature is added to your home the number one question that gets asked is how much will it cost? Our idea was to break down several steps of the installation and give approximate costs for driveway heaters.

This way home owner can see how much it can cost to hire contractors or to do some of the work by themselves. For calculating purposes we took average size driveway being 500 square feet.

Demo and excavation – $3 per square foot or on average $1500 per regular driveway.

This includes ripping old part of asphalt or concrete with excavator and completely disposing it. For home owners who start building their new home, this expense will never show up. On new lot or after home demolition, there will be no more driveway to demolish.

Purchasing materials – Electrical heater mats cost $10 per square foot. Radian heat water pipe loops cost $4 per square foot with Styrofoam boards.

Heat from water is cheaper comparing to electricity and materials used are much cheaper.

Installation of heating system – For electrical system its $3 per square foot, while pipe loop system with water will cost you $6 per square foot.

Now electrical connections are cheaper than water. Matts simply connect together and within few hours the job is almost done. The last step is to connect it to main power unit. For heated system with water pipes, installers drag and bend loops of all cross the driveway. At end connection all pipes are attached to manifold which goes to either boiler or hot water tank system.

Redoing surface of driveway – We are going to consider only Asphalt which costs $5 per square foot and concrete driveway surface at $8 per square foot.

There is no average number simply because there are at least 7 different driveway materials you can use.

To sum it all up for an average size driveway home owners are looking to spend $10500 for new heated driveway system installation.

Maintenance Throughout the Year

Hydronic system with pex tubes does not require specific maintenance. The water mix inside the pipe has nonfreezing components that prevent it from completely freezing during the winter.

However the heater or boiler is recommended to have annual inspections for proper heat supply and other details.

Electrical heated driveway mats can be inspected at connections for rust and damage that could break the circuit and shut down entire system.

Breakers and main cable is also to be inspected annually by master electrician.

Lifespan of Heating System

There is a big debate on how long driveway radiant heating system can keep on going. Electrical matts on average serve around 15 – 18 years if installed properly and maintained. Small defects and bent cables can overheat and burn out.

Hydronic heat system with pex pipes tends to serve much longer and our research shows that average lifespan is 25 – 30 years. This is due to very strong pex pipes that don’t break even if bent.

In reality, heated driveway has not been around for very long time to properly test their lifespan. On Point Remodeling suggest ensuring careful installation, annual maintenance and not allowing heavy duty vehicles on driveway that can damage surface with system underneath.

How long does driveway heated system work.

Conclusion for Walkway and Driveway Radiant Heating System

Upgrading you home or business driveway with a function to heat up and melt the snow is luxurious. It is not for everyone, but those who do install in have not been complaining.

For new home construction we definitely recommend installing heated walkways and driveway at discounted price. New builds do not require tear up, and will surfacing driveway cost. You simply add the material and installation of heating product.

On Point Remodeling can help find trusted and experienced contractors for installation of heated driveway and walkway.

editor's pick

latest video

news via inbox

Nulla turp dis cursus. Integer liberos euismod pretium faucibua